HF series platforms

Assembly principle of HF platform

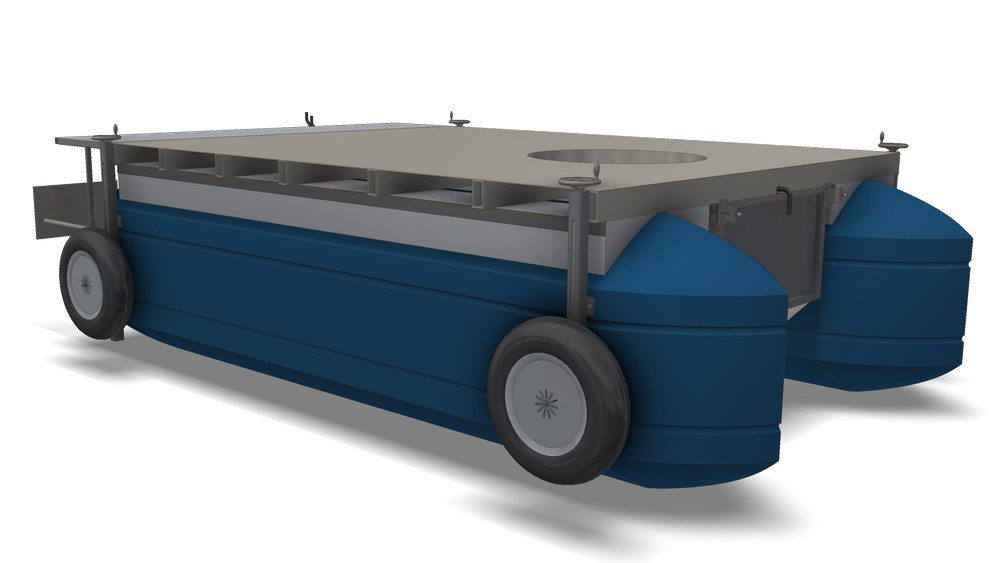

Platforms made using HF pontoons have an increased longitudinal strength due to the internally integrated metal frame. HF platforms are constructed, starting with the welding of the framing which would go inside the pontoon, after which, pontoons are attached to the sides of the frame resulting in pontoon rows. These rows are connected together with the joists mounted on the pontoon rows forming the pontoon platform. With the platform done, other elements such as decking, superstructure, railings could be assembled.

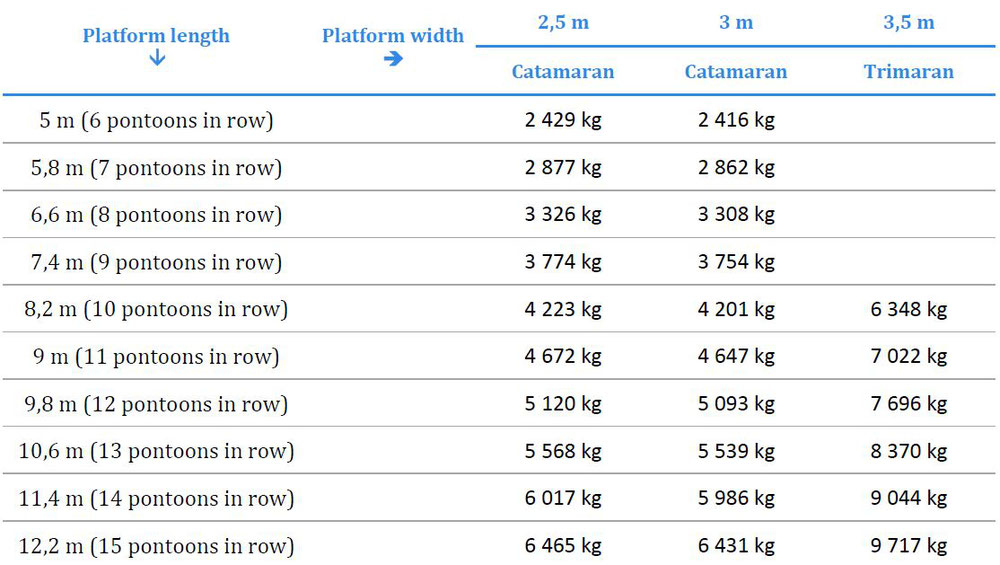

Weight lift capabilities of HF platforms

In the above given table, weight lift information for different size and type pontoon platforms is provided. Pontoon, metal framing, and fastening elements weight is accounted for already. All the other weights sum such as decking, superstructure, people, provisions, liquids, engine, luggage, equipment must fit under this number.

HF platform for sturdy long builds and special purpose ships

Platforms with HF pontoons can carry more weight per same area compared with ABC platforms. Additionally, increased longitudinal strength allows for longer builds or ones with a lot of glass elements, as well as special purpose ships.

In addition to the pontoon platform, ØSTFOLD BIL OG BÅTSERVICE AS is able to provide wooden cabins or metal framing of a superstructure without finish. Contact us to get our offer. To see some of the projects done using our pontoon floats please proceed to the gallery.

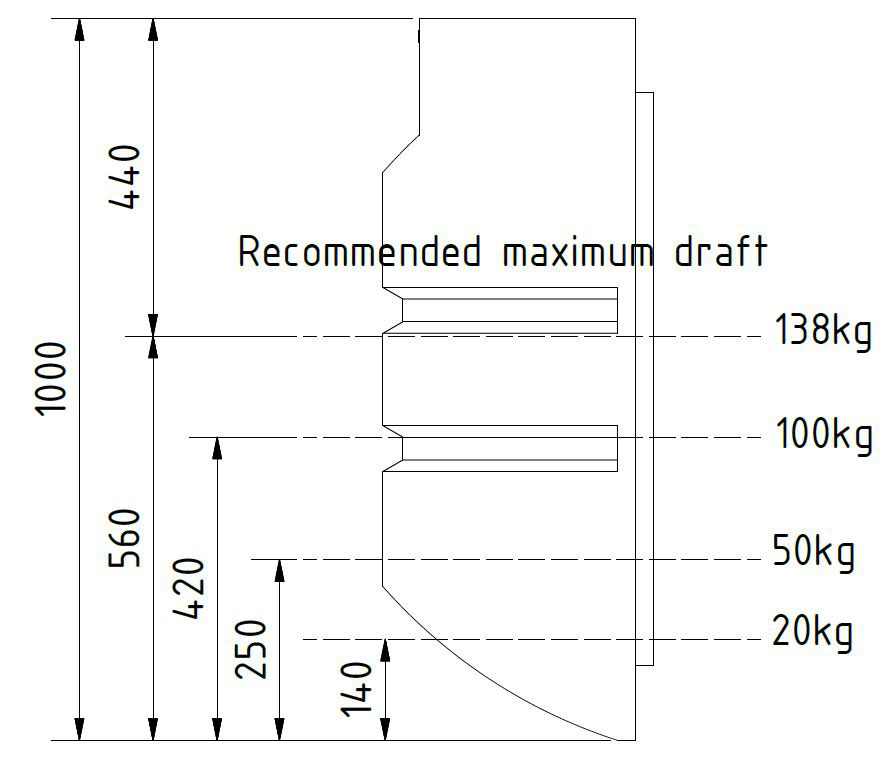

Draft of HF platform

Typical draft of HF platform is 0,56m, which allows for ships using HF pontoons to operate in relatively shallow waters.

Norsk Bokmål

Norsk Bokmål